CFD Analysis of Aerodynamic Characteristics of a Pickup Truck

Simulating 30 m/s airflow to uncover pressure hotspots and optimize drag.

Skills Gained

Research Replication

OBJECTIVE

Perform a high-fidelity CFD study to

-

Simulate 30 m/s external airflow over a 1:12 pickup-truck model.

-

Replicate & validate pressure-coefficient curves and drag forces from the 2009 Clemson & GM R&D study.

-

Execute a mesh-independence analysis to lock in an optimal ~2.9 M-element mesh.

-

Compare “tailgate up” versus “tailgate down” to quantify their effects on bed-region turbulence and overall drag.

My Process

Body Of Influence

Geometry prep

To the mesher

To the solver after 5 'Not responding'

errors 🫠

-

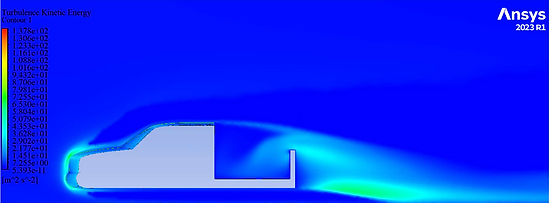

A realizable k-epsilon turbulence model used to solve turbulence flows.

Optimum Mesh chosen

Results & discussion

Velocity Contour

-

Peak velocity above roof → streamlined flow downstream.

-

Recirculating bubble in truck bed → source of extra drag.

Red zones show flow acceleration over the cab; recirculation in the bed.

-

Front bumper pressure peak correlates with drag force.

-

Pressure drop over hood → lift considerations for vehicle stability.

Pressure Contour

High pressure at bumper & windscreen due to stagnation.

Validation

Cp curves mirror the 2009 Clemson & GM study’s trends, with minor offsets attributed to reference-pressure choices and coordinate origins

tailgate up or down?

Tailgate Down

More turbulence thus increasing resistance

Tailgate Up

Less turbulence ; reduced resistance